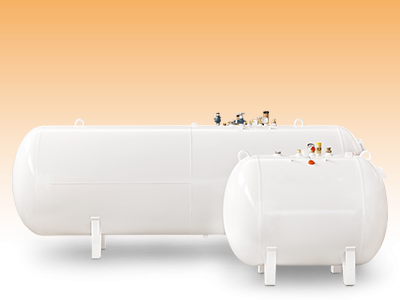

STATIC TANKS

Horizontal aboveground tanks • Horizontal underground tanks • Vertical aboveground tanks

Static tanks for LPG storage for aboveground or underground installation, according to European Directive 2014/68 / CE and CE marking. Under requirement, according to ASME VIII div. 1 and ASME marking, or adapted to the regulatory requirements and the specific requirements of the place or country of destination. All capacities, up to 400 m3.

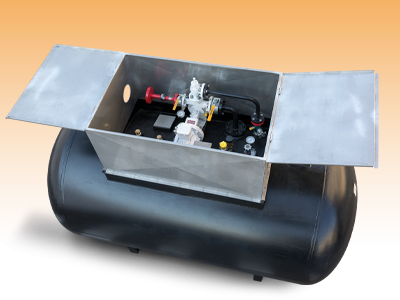

AUTO-GAS SKIDS

Horizontal aboveground SKID • Vertical aboveground SKID • Underground SKID

Autonomous units for storage and service of LPG, with pumping equipment and dispenser or filling column, integrated in the frame together with the LPG tank. With incorporated transfer equipment, it allows the supply of LPG to the vehicle in liquid phase. The whole assembly is factory-assembled ready to operate, just by fixing it to the ground with an earthing connection and providing the electrical power supply panel.

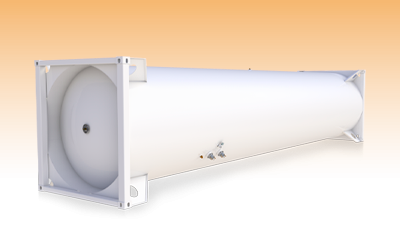

TRANSPORTATION AND SERVICE

Transportable bottles • ISO-containers • Semi-trailers

Transportable bottles, ISO-containers and semi-trailer tankers and on truck, for the transport and service of LPG, manufactured under applicable European standards and Directives (ADR, ISO, CSC,… etc.). Volumetric capacity for transport tanks and transfer equipment, adapted to the specific requirements of the client.

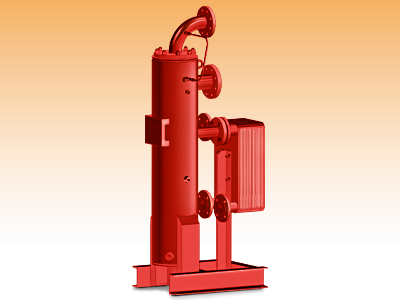

VAPORIZATION SYSTEMS

“FEED OUT” vaporization systems • Modular vaporization and heating equipment

Forced vaporization systems, which are complemented by the natural vaporization capacity of the tank, for installations with high gas consumption and limited space.